Double facer SM-10

※Structural features:

★Heating plate surface by grinding treatment, hot plate width 600mm, a total of 12 heating plate and cooling 4 m。

★Heating plate with a container board production, in line with national standards for a class pressure vessel, with pressure vessel certificate and inspection certificate。

★Hot plate with intensive gravitational roll structure. Roll adopt pneumatic lifting.

★Heating plate heat transfer pipe temperature control sub-four-segment, with a temperature display.

★on cotton use two-cylinder S type cotton belt with the tensioning device.

★lower belt adopt pneumatic tensioning.

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam。

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:12 pieces

4、hydraulic system pressure:6—8Mpa

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢475mm lower drive rubber roller diameter:¢350mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢176mm back setting belt driven roller diameter:¢176mm

3、Platen roller:¢85mm Setting roller diameter:¢86mm

4、upper belt tension roller diameter:¢155mm upper roll diameter with detuning:¢124mm

5、Lower belt tension roller diameter:¢130mm Entrusted with the roll diameter lower belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:22KW 380V 50Hz Continuous (S1) working standard

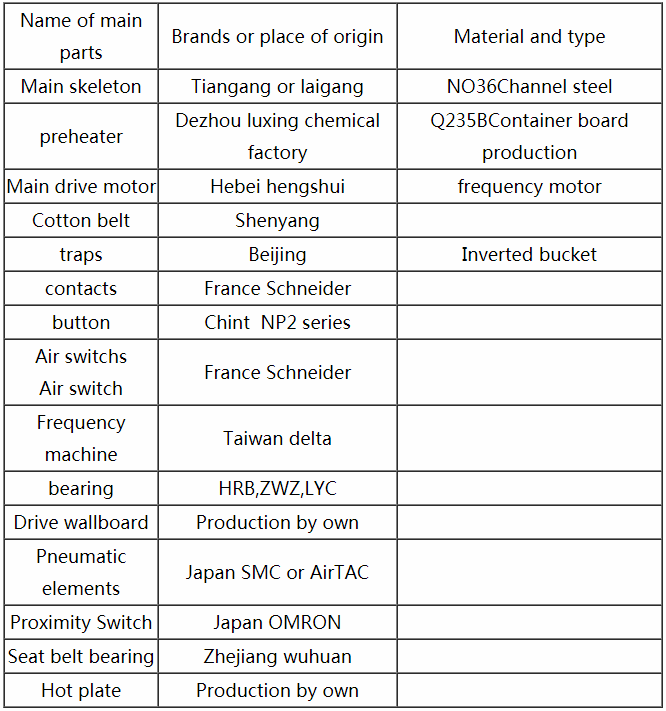

※Mainly purchased parts, raw materials and origin: